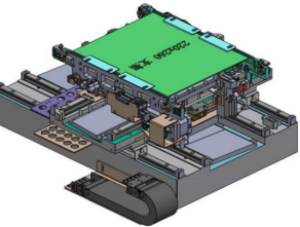

Equipment performance | Equipment parameters | |

Equipment capacity (Full test UPH) | Open PR, bottom flying shot and post-solidification inspection 75K/H (depending on the solid crystal material) | |

Equipment accuracy | Position accuracy XY | ≤±15um |

Angular accuracy θ | ≤±1°(depending on the solid crystal material) | |

Device compatible product size | Length (L) size | Max 380mm |

Width (W) size | Max 220mm | |

Crystal ring size | 6 inch | |

Reading head resolution of crystal retrieval and crystal bonding platform | 0.5um | |

Compatible chip size | 2mil*4mil-40mil*40mil(0.05mm*0.1mm-1mm*1mm | |

Crystal taking pressure of Bond head swing arm | Adjustable 30g—250g | |

Swing arm nozzle rotation | ±180°Any angle die bonding | |

Image recognition system | Resolution | 720*540Pixel |

Grayscale | 256Grayscale | |

Image recognition accuracy | ±2.5um@50mil | |

Equipment appearance parameters | Dimensions (excluding display, tricolor light & FFU) | 1480mm(L)*2060mm(W)*1800(H)mm |

Track height (from ground level) | 900mm±30mm | |

weight | 1800kg*3 | |

Equipment electrical parameters | Voltage/Frequency | 220V/50Hz |

Rated Power | 2.2KW | |

Using Compressed Air | 0.5Mpa(Min) | |

Gas consumption | 20L/Min | |