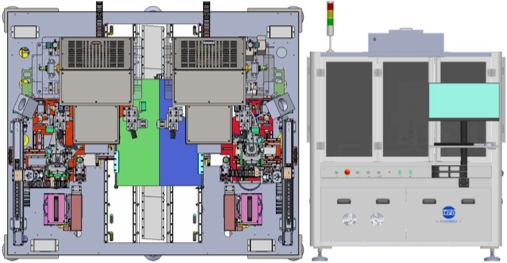

Equipment performance | Equipment parameters | |

Equipment capacity | 40K/H (depending on die bonding material) | |

Equipment accuracy | Chip position accuracy after die bonding XY | ±15μm |

Chip angle accuracy after die bonding θ | ±1° | |

Device Compatible Product Dimensions | Length (L) size | Max 800mm |

Width (W) size | Max 500mm | |